SUNDRE – Although the municipality’s planned upgrade to the wastewater treatment facility remains a work in progress, testing has begun through the use of scaled-down mobile versions of the new technology.

Chris Albert, director of corporate services, confirmed recently that the permanent structure which will eventually house the new technology remains incomplete.

“There’s still unfortunately construction delays with it,” he said.

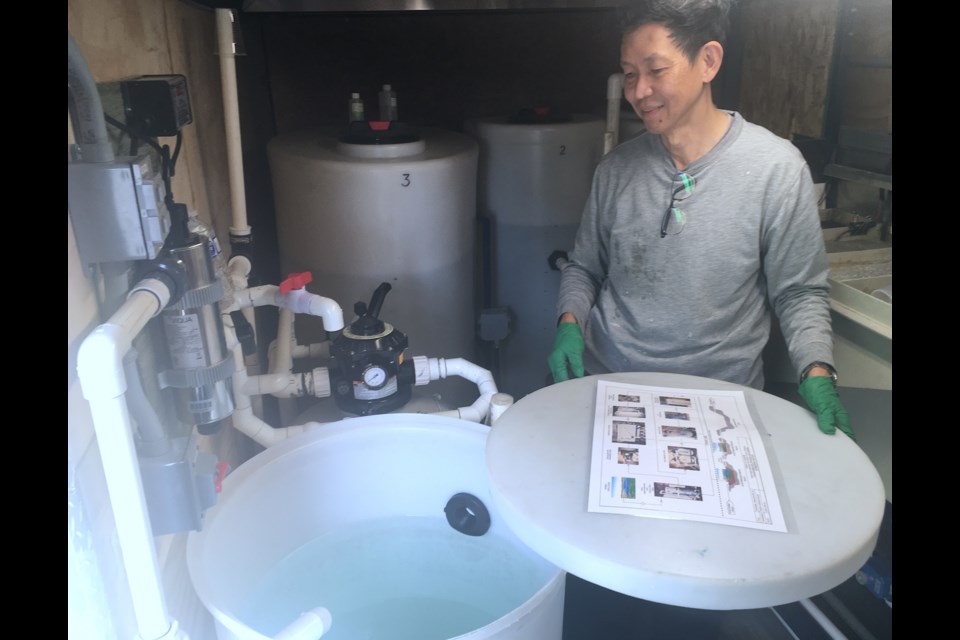

However, two scaled-down and fully-contained mobile units equipped with the technology are now on the site, he added.

“They have been testing for at least a couple of weeks,” he said. “They are, from what I understand, exact duplicates of what will be going in permanently. They’re just more mobile units."

Describing them as “fairly big,” he said they're roughly half the size of the final building. So while the technology’s finished housing structure will be about the size of a sea can, the smaller mobile units are about half that size, he said.

“These things are probably roughly the size of a car hauler,” he said.

Access to the units enabled testing to begin in mid September, he said, adding that process is being conducted between Soneera – the contractor and supplier of the technology – and the provincial government.

“Soneera is working with Alberta Environment to prove out the technology,” he said.

Eventually, the municipality will take over the facility, but not before the technology has been approved by Alberta Environment, he said.

“Once everything is proven out and we get the sign-off from Alberta Environment and everything’s done, then we take it over,” he said.

“But until that happens, we have no risk associated with it.”

Linda Nelson, chief administrative officer, said the scaled-down modulars enabled the testing to begin in the absence of the full-size facility.

The decision to proceed, she said, followed conversations with Alberta Environment to determine the best alternative to move forward in the face of ongoing delays including supply issues that have hampered the completion of the structure that will eventually house the new technology.

“We felt it was more appropriate to start testing the modular,” she said. “So, we did get the modular completely built; it’s an exact replica of the full-scale build.”

The municipality has also submitted documentation to Alberta Environment to begin the testing under the Environmental Protection and Enhancement Act, she said.

“It’s for the short-term testing of a pilot wastewater treatment system,” she said.

Although never-before deployed in Alberta, the technology is in use in at least one municipality in Saskatchewan called Unity. The process involves an electro-chemically based water treatment system for municipal sewage.

“It’s a three-staged, electro-chemical system design,” she said.

The first stage involves the removal of contaminants through electro-flocculation while the second stage treats ammonia and stage three disinfects, she said.

Additionally, the testing of the technology – conducted by analyzing samples of treated water – is being done by two parties. So while initial testing started in mid-September, official testing involving an unbiased third party began on Oct. 11, she said.

“We wanted to have a baseline for what we were testing against,” she said about why some testing had started in September.

“The water samples will be taken into the lab in a sealed jar by an unbiased individual,” she said.

Testing will continue for one year, under what Nelson described as “quite a rigorous regime” that has already yielded early promising results.

“The test results from the samples that we’ve submitted so far have been exceptionally good,” she said, acknowledging that the process is just getting started and that long-term averages have yet to paint a clearer picture.

But the data to date seems to demonstrate no shortage of potential.

The provincial government’s standards for the BOD – biological oxygen demand – in treated water is to be under 20 milligrams per litre, she said.

“When we tested from our raw water, it was at 71,” she said, adding a test result from “Sept. 24 came back at 2.2 milligrams per litre.”

The chemical biological oxygen demand’s provincial standard is also less than 20 milligrams per litre, she said, adding early tests of untreated water showed about 61 before the process brought that amount down to less than 2.

As for suspended solids, the provincial standard calls for effluent to contain no more than 20 milligrams per litre, she said, adding the test of raw sewage came in at 173 milligrams. After being treated, the amount of suspended solids had plummeted to less than three milligrams per litre, she said.

“It’s huge,” she said.

Phosphorous also came in substantially lower than provincial standards, which regulate a maximum of 0.5 milligrams per litre. Raw testing yielded 4.19 milligrams but after being treated, the tests showed it dropped significantly down to 0.0067, she said.

There have also been preliminary tests done for ammonia and e. coli, but those results were not yet immediately available when Nelson spoke with the Albertan on Oct. 13.

The company deploying the technology – Soneera Water – is doing three weekly grab tests, while the municipality has an unbiased, third-party contractor called Magna Engineering that is conducting one weekly test, she said.

Above and beyond the treated effluent’s quality, the municipality is also studying throughout the testing phase the facility’s potential to expand its capacity courtesy of the technology, which is billed as being able to process much larger volumes in vastly shorter spans of time than traditional systems.

Additionally, the “operating costs in comparison to other water treatment facilities” are also being tracked, she said.

Provided the technology passes the testing phase with flying colours, Alberta Environment would then approve and accept the technology, she said.

“Standards and guidelines would be written around this technology, and we would be doing the full-scale build,” she said.

In other words, the permanent housing structure that’s been delayed will at this point likely not be constructed before the testing of the technology on the modulars is complete, she said.

“It’s been such a long road; so many delays and complications that were really beyond our control,” she said.

“But now, I mean it’s really exciting now that we’re finally able to start this.”

The roughly $11.5-million upgrade will not replace the lagoon system, but rather substantially accelerate the existing facility’s ability to process larger volumes of wastewater while also improving the quality of effluent – or treated water – that is released back into the Red Deer River.

- RELATED: Sundre wastewater treatment facility suffers ‘one hold up after another’

- RELATED: Concrete foundation for Sundre’s new wastewater treatment upgrade complete

- RELATED: Construction starting on Sundre’s pilot sewage treatment tech

- RELATED: New state-of-the-art pilot Sundre facility receives $7.5 million

- RELATED: Cutting-edge wastewater facility could become trendsetter